Introduction

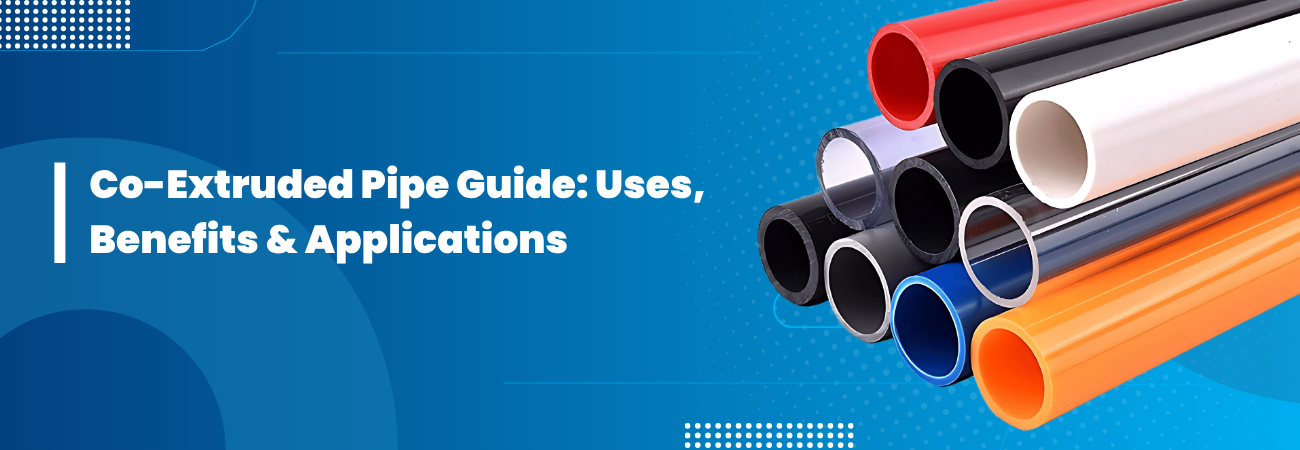

In the world of advanced plastic manufacturing, co-extruded pipe has emerged as a game-changer. This innovative product leverages the power of co extrusion plastic to deliver enhanced functionality, performance, and durability across industries like construction, lighting, and automotive.

Whether you’re a manufacturer, engineer, or buyer searching for durable tubing solutions, understanding co-extruded pipes and related co extruded profiles can help you make informed choices.

What Is a Co-Extruded Pipe?

A co-extruded pipe is a multi-layered tube created using a process called co-extrusion, where two or more materials are simultaneously pushed through a single die to form a single composite pipe. Each layer in the pipe serves a specific purpose—such as improving strength, flexibility, UV resistance, or aesthetics.

Key Features:

- Multi-layered structure

- Enhanced material performance

- Customizable properties

- Cost-efficient for large volumes

How Co Extrusion Plastic Technology Works

Co-extrusion plastic is a process in which two or more molten plastic materials are simultaneously shaped into a single product with multiple layers. This technique enables manufacturers to merge the advantages of different plastics—like strength and flexibility—into a unified pipe or profile.

The Co-Extrusion Process Includes:

- Feeding: Different plastic resins are loaded into separate extruders.

- Melting: Resins are melted at controlled temperatures.

- Merging: The molten materials merge through a multi-channel die.

- Shaping & Cooling: The newly formed pipe is shaped and rapidly cooled.

- Finishing: Pipes are cut to required lengths and inspected.

This process is widely used not only for pipes but also for various co extruded profiles like window trims, edge seals, or protective housings.

Why Use Co-Extruded Pipe? Top Advantages

Co-extruded pipes bring numerous benefits over traditional single-layer pipes, making them suitable for specialized and high-performance applications.

Major Advantages:

- Material Optimization: Use premium material only where needed, saving cost.

- Durability: Outer layers can be UV-, chemical-, or abrasion-resistant.

- Functionality: Inner layers can be smoother or have anti-microbial properties.

- Custom Design: Ideal for products with specific physical or aesthetic needs.

Applications of Co-Extruded Pipes Across Industries

The use of co-extruded pipe is growing across sectors thanks to its adaptability and performance benefits.

1. Construction & Infrastructure

- Underground drainage and conduit systems

- Hot and cold water piping

- Structural reinforcement

2. Lighting & LED Systems

- Pipes and profiles that work as diffusing LED strips

- Light guides with high transparency and diffused outer coatings

3. Medical & Pharmaceutical

- Multi-layer tubing with different internal and external properties

- Sterile packaging tubes

4. Automotive

- Tubes for fuel lines, air conditioning, and wiring channels

- UV and heat-resistant profiles

What Are Co Extruded Profiles?

Co extruded profiles are similar to co-extruded pipes but are often flat, angular, or complex in shape. They are used extensively in windows, doors, display frames, and LED housings.

These profiles often combine rigid and flexible plastics, allowing for easy snap-fit assembly or integrated sealing.

Example Applications:

- LED enclosures and diffusers

- Door seals and edge trims

- Electrical cable protectors

Co Extrusion in LED Lighting: Enhancing Light Diffusion

One of the most innovative applications is in the LED lighting sector, especially in creating diffusing LED strips.

Using co extrusion plastic:

- The inner layer ensures light transmission efficiency

- The outer layer acts as a light diffuser, softening harsh LED points

This dual-layer setup enhances aesthetic appeal while also protecting the LED strip from dust, moisture, and impact.

Who Should Consider Co-Extruded Pipes?

Co-extruded pipe is ideal for:

- Product designers seeking multi-functional tubing

- Engineers looking for specialized material combinations

- Manufacturers needing durable yet cost-effective solutions

Whether you need enhanced barrier properties, customized aesthetics, or performance improvements, co extrusion plastic can offer a tailored solution.

Final Thoughts:

The increasing demand for performance-driven, sustainable, and multifunctional components makes co-extruded pipe technology more relevant than ever. Whether it’s in smart lighting solutions, infrastructure, or medical devices, co extrusion plastic offers a path to efficient and high-quality product development.

FAQs

Co-extrusion combines multiple materials into one product, while single extrusion uses only one material throughout.

Yes, they typically offer improved strength, chemical resistance, and longevity compared to single-layer pipes.

Absolutely. They can be designed with UV-resistant outer layers ideal for outdoor conditions.

They use two plastics—one clear for light transmission and one frosted or opaque to diffuse the light.

Many co-extruded pipes are recyclable, but it depends on the materials used. Some may require separation before recycling.

Common materials include PVC, polycarbonate, polyethylene, and thermoplastic elastomers.

Industries like construction, lighting, electronics, and automotive frequently use these profiles for their design and material flexibility.

Yes, they can be tailored in terms of layer composition, thickness, color, and functionality.